A BEGINNER'S GUIDE TO Branding APPAREL.

So you want to launch a t-shirt or clothing brand soon?

That's awesome – you've come to the right place.

Whether you're deciding to start a streetwear label, need band merch or a business uniform, we will have a solution to meet your needs. But with so many options, it is hard to know where to start.

So before you start with a quote, it's a good idea to learn about different print techniques, t-shirt fabrics, design specifications, and how many you need to order. It's also important to consider how your customer will use your shirts since some t-shirt printing techniques may produce a longer-lasting product.

With many variables to consider, it may feel overwhelming at first. However, once you understand the basics, you'll be able to design unique graphics that work for your particular requirements, and this will save you money in the long run.

This beginner's guide gives you a quick yet complete rundown of the ins and outs of t-shirt printing.

THE HISTORY OF THE T-SHIRT PRINTING INDUSTRY

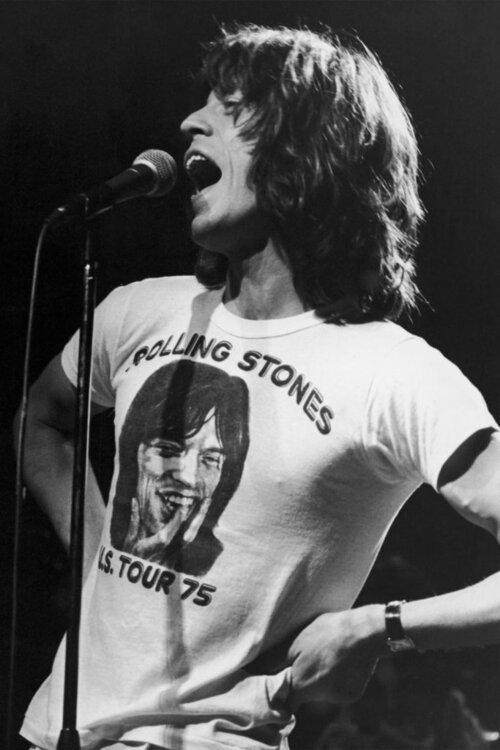

While the exact history of t-shirt printing is unclear, screen printing is the oldest (and still the best) print method, and most believe that screen printing has its roots in ancient China. But it wasn't until the 1950s when screen prints started to appear on a popular new shirt style, the T-Shirt.

Since then, printed t-shirts have been the mainstay of almost everyone's wardrobe. Since the adoption by the early hippies, rock bands to high-end fashion and streetwear, printed t-shirts have continued to grow in popularity.

WHAT ARE THE VARIOUS T-SHIRT PRINTING TECHNIQUES AVAILABLE?

There are three primary t-shirt printing techniques available today: screen printing, heat transfers, and direct to film (or DTF) printing. There is also dye sublimation, but this is more suited to polyester sportswear, so let us focus on the cotton and streetwear options.

While each printing technique has its unique advantages and uses, screen printing is still the most popular and, for most purposes, is still the best option. Screen printing on t-shirts has been around for over 100years with years of research & development that continues to this day.

Before simply deciding if screen printing is suitable for you, let's look at each t-shirt printing technique in detail. You may find that other print methods may work better for you, depending on your specific needs.

1. SCREEN PRINTING

Screen printing is easily the most popular and commonly used clothing print method. One of the biggest reasons why screen printing is the most popular t-shirt printing technique is its quality product with accurate colours and various ink options. Inks used in screen printing tend to be more opaque than those used in other printing techniques, which results in a longer-lasting product with more accurate and vibrant colours.

Screen printing offers the best bang for your buck when producing a bulk order and allows the most consistent print quality. If you are only expecting to print a few t-shirts here and there, screen printing is not the way to go.

PROS OF SCREEN PRINTING:

Vibrant, Long-Lasting Colours – Inks are bold, opaque, and built to last through many washes.

Great for Bulk Orders – Most cost-effective method for larger runs.

High Quality, Consistent Results – Delivers sharp, professional finishes with excellent colour accuracy.

Versatile Ink Options – Choose from plastisol, water-based, puff, metallic, glow-in-the-dark, and more.

Works on a Wide Range of Fabrics – Ideal for cotton, poly blends, and even some performance materials.

Scalable – Once set up, it's fast and efficient to print large quantities.

Excellent for Bold Designs – Perfect for logos, artwork, and solid colour prints.

Durable Print – Properly cured prints resist fading, cracking, and peeling.

CONS OF SCREEN PRINTING:

You need to meet a minimum order to be cost-effective.

Each new design or size requires set-up costs incl film, and screens.

You need to increase your order size with each additional colour in your design.

Full-colour designs require a large bulk order of at least 100pcs.

2. SUPACOLOUR TRANSFERS.

Supacolour transfers are created using a hybrid digital (the colour) screenprint (a white, adhesive base) process to print your design onto a special transfer sheet. Next, we position your heat transfer on your t-shirt and use a heat press to press or "melt" your design onto the t-shirt permanently.

One of the best advantages of Supacolour transfers is the low minimums (12pcs) for a full-colour print. Supacolour prints can also achieve a very high-resolution image. We can also hold your pre-paid transfers to "print on demand."

PROS OF SUPACOLOUR TRANSFERS

High-quality prints that are very close to screen printing.

Cost-effective full-colour prints.

Low Minimums for multicolour designs (starting at 10pcs)

Minimal set-up costs compared to screen printing.

Durable: no cracking or fading, even after 50+ washes.

CONS OF SUPACOLOUR TRANSFERS

Suitable for full-colour prints only.

You need to order a minimum of 12 transfers.

The print can feel a little thick compared to a screen print.

Durable, but not as durable as a screen print.

3. DTF TRANSFERS.

Looking for a flexible, no-minimum option for custom prints? DTF (Direct-to-Film) transfers are a great solution for short runs, samples, or one-off designs. They allow for full-colour prints with fine detail, and can be applied to a wide range of garments. While they’re not as durable as Supacolour, they’re a fast, affordable choice for quick-turnaround jobs. Whether you're testing a new design or fulfilling small custom orders, DTF offers versatility without the bulk order commitment.

PROS OF DTF TRANSFERS

High-quality images.

Full-colour prints. Great for vibrant designs, gradients, and fine details.

No Minimum Order. Perfect for one-offs, samples, or small batches.

Quick Turnaround. Fast production makes it ideal for tight deadlines.

CONS OF DTF TRANSFERS

Less Durable Than Supacolour or Screen Printing – May not hold up as well over time, especially with heavy washing.

Can Feel Slightly Plastic – Some transfers have a more noticeable hand feel compared to other methods.

Lower Stretch Tolerance – Not ideal for highly stretchy or performance fabrics.

May Crack or Fade Sooner – Especially if not applied or cared for properly.

Not Ideal for Large Runs – Becomes less cost-effective than screen printing at scale.

4. EMBROIDERY.

Embroidery is a classic and highly durable decoration method that adds a premium, textured finish to garments. It’s especially popular for workwear, uniforms, hats, and branded apparel where a long-lasting, professional look is essential. One of the biggest advantages of embroidery is its durability — stitched logos and designs won’t fade, peel, or crack over time, even after frequent washing.

Embroidery is most cost-effective for medium to large runs with smaller and simpler designs, especially those using solid colours. It's not ideal for detailed artwork or small one-off jobs, and complex gradients or fine lines don't translate as well in thread. But for clean, bold branding with a high-end finish, embroidery is hard to beat.

PROS OF EMBROIDERY

Extremely Durable – Stitched designs won’t fade, crack, or peel, even after heavy washing.

Professional Look – Adds a premium, high-end finish ideal for uniforms, polos, jackets, and caps.

Textured, 3D Appearance – Gives depth and dimension that printing can’t achieve.

Works on Thick or Textured Fabrics – Perfect for items like hats, heavy workwear, and outerwear.

Great for Bulk Orders – Especially cost-effective when running medium to large quantities.

CONS OF EMBROIDERY

Not Ideal for Fine Detail – Small text, intricate designs, and gradients don’t translate well in thread.

Limited Colour Blending – Unlike printing, embroidery can’t achieve smooth fades or complex colour transitions.

Can Be More Expensive – Higher cost per unit, especially for small orders or large, complex designs.

Not Suited for Lightweight Fabrics – May cause puckering or distortion on thin materials like light tees.

Less Flexible Placement – Works best on flat, stable areas; not ideal for seams or stretchy sections.

Thread Count Limits Design Size – Large designs may require simplification or incur additional costs.

Longer Setup Times – Digitising and machine prep take time, especially for new designs.

🧵 Apparel Decoration Method Comparison

| Feature / Method | Screen Printing | Embroidery | DTF Transfers | Supacolour Transfers |

|---|---|---|---|---|

| Best For | Bulk t-shirts, hoodies, promo gear | Uniforms, workwear, caps, polos | Short runs, samples, full-colour designs on various fabrics | High-detail, full-colour designs with durability |

| Minimum Order | Usually required (due to setup costs) | Small to medium (more cost-effective at scale) | No minimums | Low minimums (varies by supplier) |

| Detail & Colour Range | Solid colours, sharp lines, limited gradients | Best for simple, bold logos | Full colour, good detail (not ideal for tiny text) | Exceptional – prints millions of colours, near photo quality |

| Durability | Excellent (when properly cured) | Top-tier – won’t fade or peel | Good (not as durable as Supacolour or embroidery) | Excellent – tested to last over 70 washes |

| Feel on Fabric | Can feel heavier on large prints | Textured, raised stitch feel | Soft and flexible | Smooth, light feel with strong adhesion |

| Setup Time | Longer (separate screens for each colour) | Medium (requires digitising) | Fast | Moderate |

| Works On | Most garments, especially cotton & blends | Hats, heavy garments, thicker fabrics | Wide range – tees, bags, jackets, etc. | Almost anything – with fabric-specific options |

| Eco-Friendliness | Depends on inks (water-based = better) | Thread = low waste, no chemicals | Less eco-friendly (plastic film, petroleum-based inks) | Water-based inks, OEKO-TEX certified |

| Personalisation | Difficult (one design per screen) | Doable, but time-intensive | Easy – ideal for names or small-run variations | Can be done, but not ideal for highly personalised runs |

WHICH COTTON IS BEST FOR ME?

Cotton is cotton, right? Not so fast, not all T-shirts are the same, and the fabric can affect your print. There are two main fabric types, and you may prefer a super soft fabric or like the old school feel of rough carded cotton.

CARDED COTTON.

Carded open-end is a cheaper way of turning cotton into "open-end" yarn. In this method, fibres are bound by a wrapped fibre that runs perpendicular to the bundle. Up close, you can see that carded open-end fibre is bulky, fuzzy and creates an uneven knit. These are a durable, cost-effective option. These are a popular streetwear option, with Alstyle and Gildan having that traditional American fit and feel.

COMBED RING-SPUN COTTON.

Ring-spun cotton yarn is smoother and longer than open-end yarn. The term "ring spun" means that the yarn goes through an innovative spinning process designed to thoroughly soften and straighten each fibre. Our most popular AS Colour Shirts are combed ring-spun cotton with a fine weave making it ideal for printing – the best in the market and available in various weights. Don't be fooled by the soft feel; 180-220gsm ring-spun t-shirts are our most durable and colourfast T-Shirts.

Choosing the Right Print Method for Your Brand

Picking the right print method isn’t just about your preferences—it’s about what works best for your customers, your design, and your budget. Here are a few key things to think about before locking it in:

1. Who’s your customer?

Are you targeting fashion-forward buyers who expect the premium screen prints seen in major retail streetwear and surf brands? Or are you looking for something more flexible like DTF Transfers for on-demand, smaller-batch jobs?

2. What’s your order volume?

It’s always smarter to underestimate than overestimate. You’ll save more by reordering than by sitting on leftover stock. Starting small and scaling up is a great way to keep cash flow healthy.

3. How complex is your design?

Full-colour graphics on low quantities can be costly with traditional methods. In that case, consider reducing your colour count, increasing your quantity, or switching to one of our digital print options like DTF or Supacolour.

4. What garments are you printing on?

We stock a wide range of blank apparel—American Apparel, AS Colour, Cloke, Gildan, Thread Project, Urban Apparel and more—at competitive wholesale prices to suit any style or budget.

Once you've considered the above, the best print method will likely become clear. For example, if you can meet the minimums, screen printing is often the most cost-effective and high-quality option over DTF transfers.

Need help deciding? We’re here for that.

Submit a quote using our online form or chat with us live—we’ll help bring your vision to life.