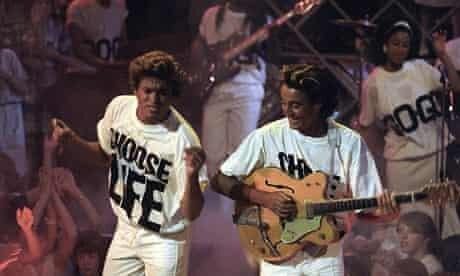

A Beginner's Guide to Printing Clothing.

So you want to launch a t-shirt or clothing brand soon?

That's awesome – you've come to the right place.

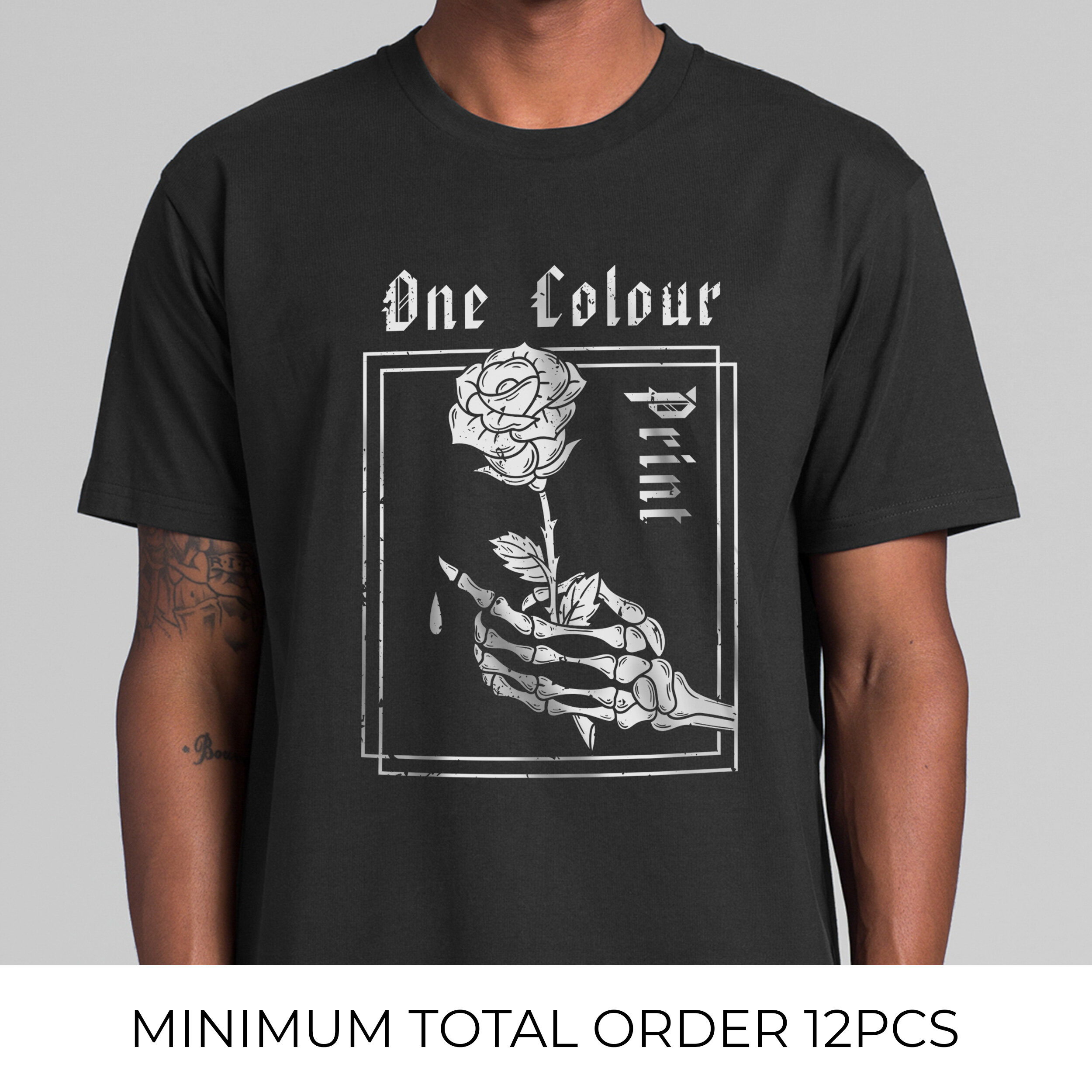

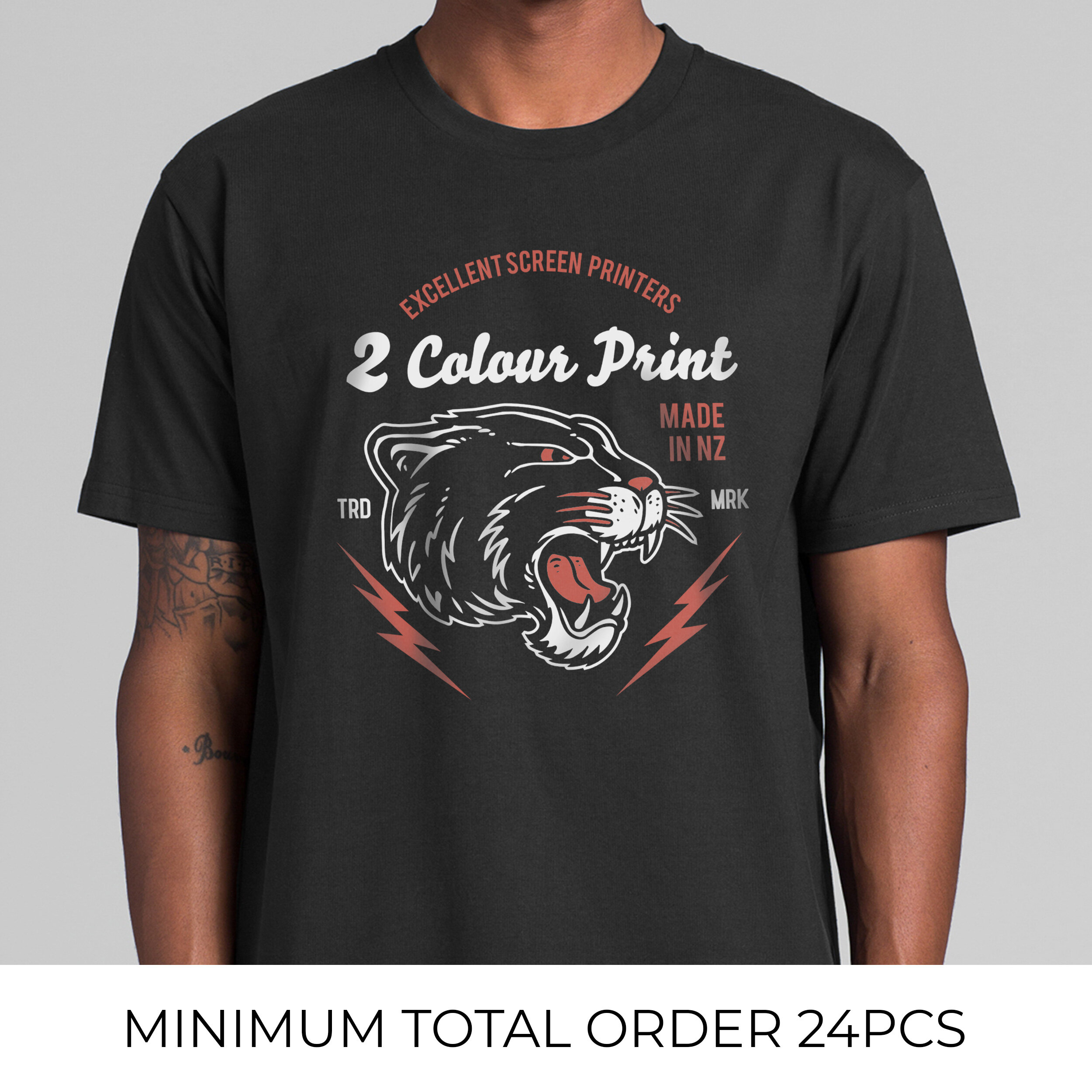

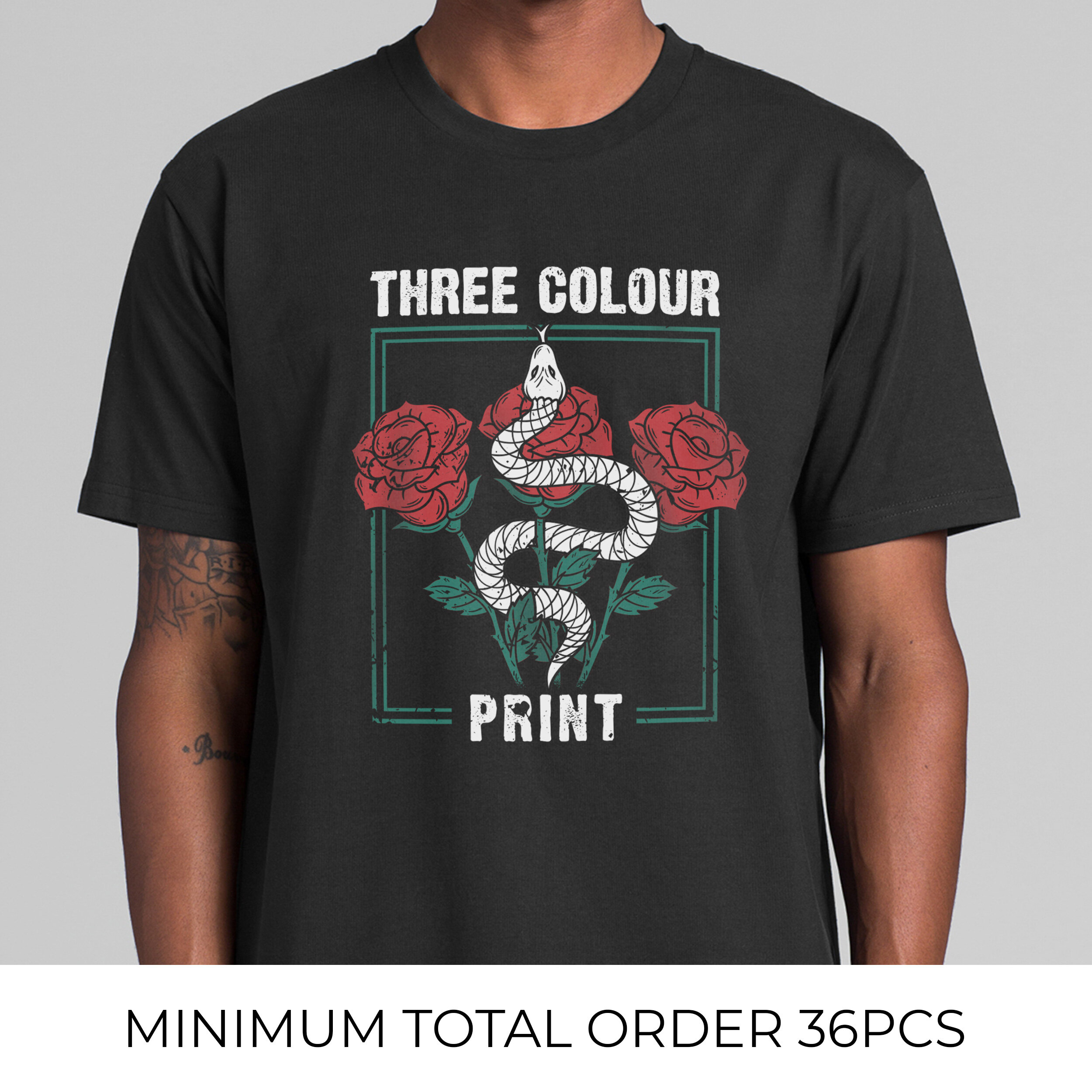

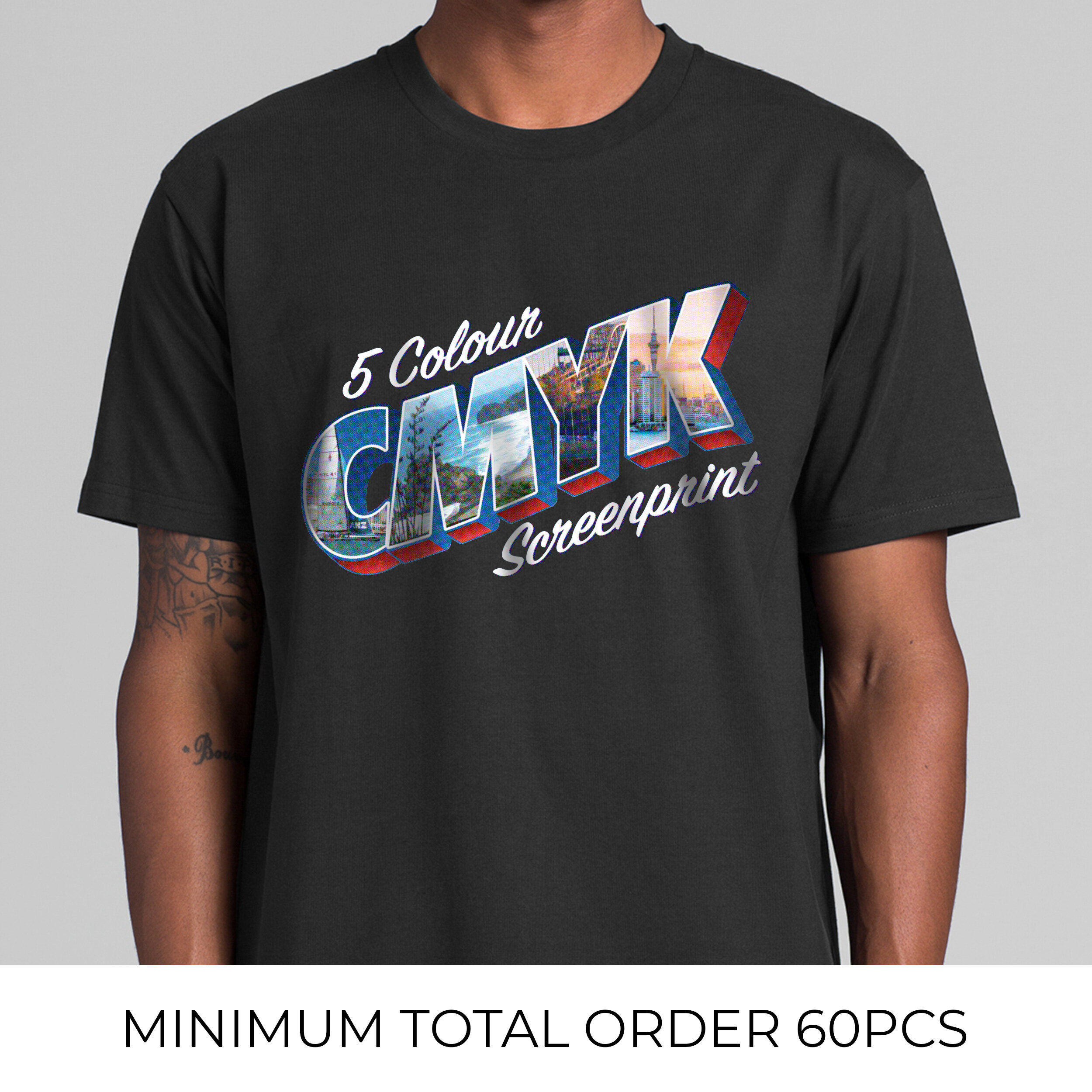

Whether you're deciding to start a streetwear label, need band merch or a business uniform, we will have a solution to meet your needs. But with so many options, it is hard to know where to start.

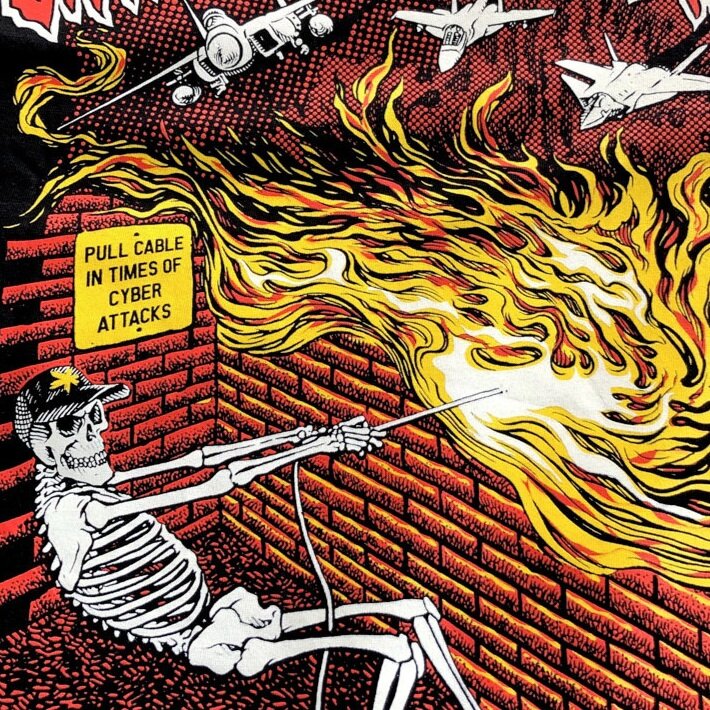

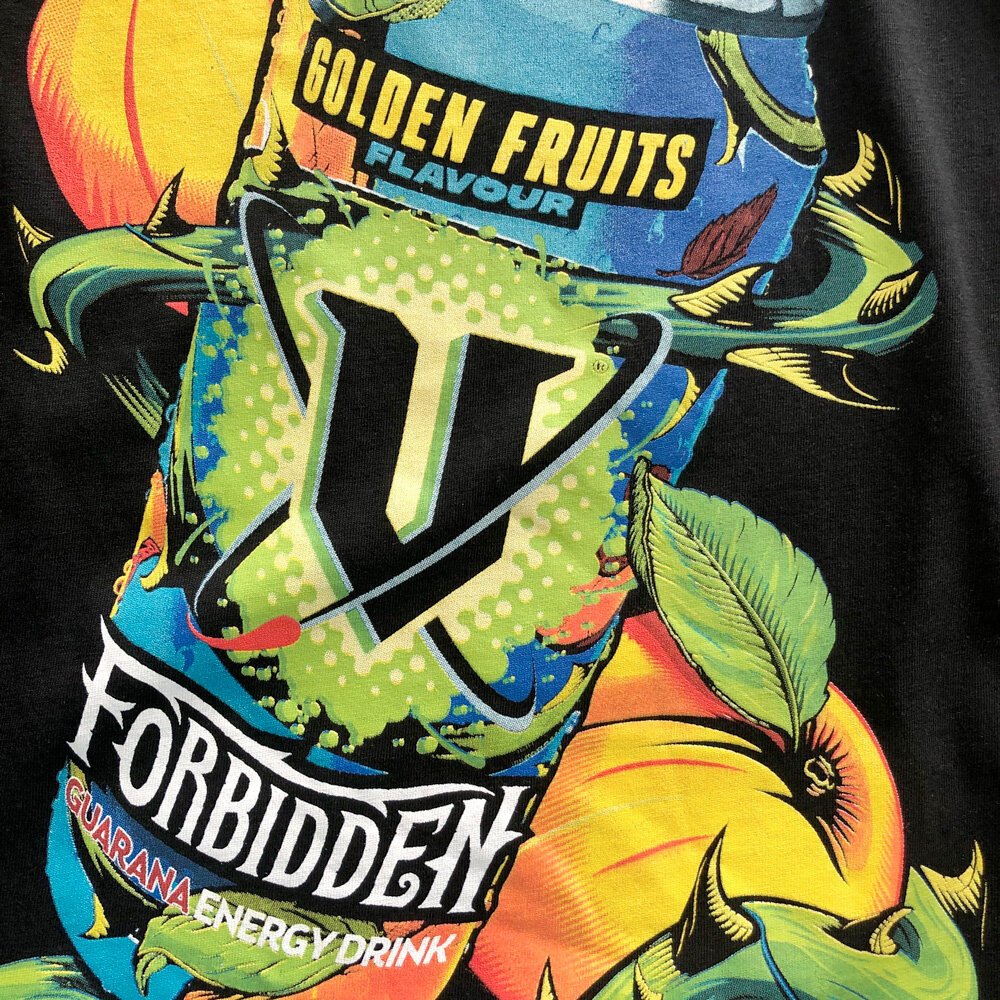

So before you start with a quote, it's a good idea to learn about different print techniques, t-shirt fabrics, design specifications, and how many you need to order. It's also important to consider how your customer will use your shirts since some t-shirt printing techniques may produce a longer-lasting product.

With many variables to consider, it may feel overwhelming at first. However, once you understand the basics, you'll be able to design unique graphics that work for your particular requirements, and this will save you money in the long run.

This beginner's guide gives you a quick yet complete rundown of the ins and outs of t-shirt printing. Let's start

What is t-shirt printing?

The is the process of applying a graphic to a t-shirt. It sounds simple, but there are many ways of printing your shirt, but we will focus on the best commercially printed t-shirts for retail sale.